Why would you want to change the speed of your DS? Unlike regular computers and some other game systems like the PSP, DS (and GBA) games always expect the handheld to run at exactly the same speed. When you speed up or slow down the clock, the game speeds up or slows down. This is great for making your games harder or easier. It's also useful for squeezing some extra clock cycles out of the hardware so you can make more powerful homebrew apps. You can also show off how L33T you are to your friends if you are into that sort of thing (or if they even care).

What you need:

- Nintendo DS Lite

- GBAccelerator DS overclocking chip

- Tri-Wing Screwdriver

- Small Phillips screwdriver

- 30 AWG kynar wire-wrap wire

- Low-wattage, fine-tipped soldering iron

- Solder wick (desoldering braid)

- Fine, rosin-core solder

- Wire cutters

- Wire stripper

- Needle-nose pliers

- Electrical tape

- Double-sided tape

- Utility Knife

- Cup or bowl to contain parts

Take the DS Lite Apart

Turn the DS Lite upside down. Use a phillips screwdriver to remove the battery cover.

Remove the battery.

Remove the stylus.

Remove the GBA cartridge hole plugger thingy.

Use a phillips and a tri-wing screwdriver to remove the eight screws from the back of the DS. Note: two of the screws are hidden under stick-on rubber feet. Use a utility knife to carefully peel them off so you can access the screws underneath. Try to set the feet somewhere where they'll stay sticky.

Put the screws in your parts container or you will never see them again.

Lift the back cover off of the DS. The bottom edge may need a little prying, but it should just snap apart.

Carefully remove the L and R buttons if they haven't popped off and fallen on the floor yet. Be careful when doing this; the pin and spring in these buttons fall out very easily and are easy to lose. Put them in your parts container when you find them.

There should be one screw left holding the PCB in place. Remove it.

Disconnect the black antenna wire from the RF module and pull it out from under the game slot assembly.

Disconnect the white microphone wire from the PCB near the RF module and bend it out of the way.

Disconnect the small ribbon cable from the connector near the RF module. Do this by flipping the black part of the connector up and sliding the ribbon out.

Flip the PCB and LCD screen together up out of the case. They will hinge on the ribbon cable that goes to the top screen.

Disconnect the remaining two ribbon cables. Do this by flipping the dark-grey part of the connectors up and sliding the ribbon out.

Place the LCD touch screen back in the case and set them aside. Now you have the PCB separate from the rest of the DS so you can work on it.

Pull straight up on the RF module until it comes free of the PCB. Set it aside.

Remove the Existing Crystal

There are four metal tabs that hold the game slot assembly onto the PCB. Desolder these. Solder wick is probably the easiest, but use whatever solder kung-fu works for you.

Lift up on the slot assembly. It will swing back on the pins which are still attached to the PCB. Now you have easy access to cryxtal X1.

Desolder and remove the crystal. If you mangle it that's okay since you won't ever need it again.

Attach a wire to one of the solder pads where the crystal used to be. This diagram shows you exactly which one:

Bend the slot assembly back into place and re-solder it to the PCB.

Install the GBAccelerator DS

Flip the PCB over so that the front side is facing up.

Solder the three button wires (blue in diagram) and the LED wire (green in diagram) to their respective solder points. Route the wires across the board as shown in the diagram. This is important so that they don't interfere with any buttons, standoffs, etc. Let them hang off the edge for now.

GBAccelerator DS Lite Front Connections | |

| LED | Green |

| BUTTON | P02 |

| BUTTON | P08 |

| BUTTON | P09 |

Lay the board next to the top half of the case.

Reconnect the ribbon cable that goes to the top screen. Note: the ribbon connectors in the DS Lite don't slide back together very easily. Make sure you slide the ribbon all the way in before flipping the latch back down or DS won't even boot.

Lay the LCD touch screen on the PCB and reconnect its ribbon cable.

Flip the LCD/PCB combo over into the top half of the case. Make sure the screen lines up with its opening. As you lower the board into position the tuft of wires you connected to the other side of the board should bend up and around the edge of the PCB.

Reconnect the small ribbon cable and the white microphone wire.

Replace the screw that held the PCB into the top half of the case.

Use double-sided tape to stick the GBAccelerator DS chip to the PCB. Make sure you place it in the position shown or there might not be enough room for it when you go to put the bottom of the case back on.

Make the remaining wiring connections as shown in the diagram. Be careful not to hold the soldering iron on any connection for too long or you could lift the pad from the DSAccelerator or DS board.

GBAccelerator DS Lite Back Connections | |

| GND | GBA cartridge slot pin 32 |

| V+ | GBA cartridge slot pin 1 |

| CLK | Solder pad where xtal used to be |

Once you are done you will (or at least should) end up with something that looks like this:

If your installation looks different, go fix it!

Put the DS Lite Back Together

Now you need to make a little extra room in the back cover for the chip you just added. Remove the three screws that hold the stylus channel onto the back cover.

Remove the stylus channel. Use a utility knife to trim off the middle screw tab (the one that had the red arrow pointing to it).

Re-install the channel, but remember now you only need two screws. Save the third one for your next project.

Reinstall the RF module onto the DS Lite PCB.

Run the black antenna wire back under the slot assembly and connect it to the RF module.

Very carefully put the L and R buttons (including their pins and springs) back into place.

Gently lower the back cover onto the rest of the DS Lite. It should sit back down into position without requiring much force. If it feels like something is hitting the GBAccelerator chip, use needle-nose pliers to gently scoot the chip around until it is out of the way.

Replace the remaining screws that hold the back cover on.

Replace the two rubber feet that you had to remove.

Reinstall the battery.

Reinstall the battery cover.

(You probably want to leave the stylus and cartridge-plugger thing out so you can play.)

Flip the handheld over, put a game in and open the screen because it's time to test out your handiwork!

Testing Out Your Handiwork

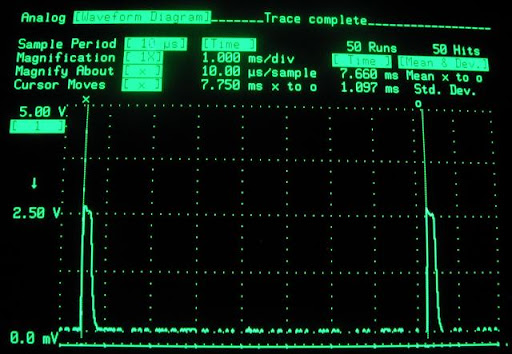

Turn on the DS Lite. It should boot just like you hadn't spent the last hour or ten modifying it.

Start whatever game you inserted. It should look pretty normal too.

Press L, R and Select. Your game should start running faster now, and the power LED should start blinking to indicate that you are in "fast" mode (1.4x).

Press L, R and Select again. The game will go even faster and the LED will double-blink to let you know that you are in "ultra" mode (1.8x).

Press the buttons again. Now your game will be running much slower and the LED will be fading in and out ("slow-motion" mode, .66x)

One more press of the magic button combination will bring you back to normal, boring 1x.

Congratulations, you now have an overclocked Nintendo DS Lite! You even have a part left over, which is usually a good sign that you did a project right.

Credits to: N-Ds Mods